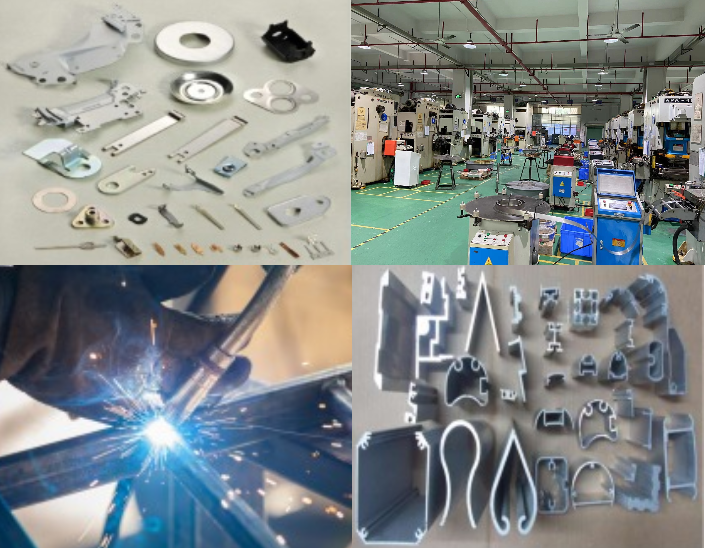

HT is a global company engaged in the engineering, design and manufacture of high precision custom solutions. With offices and factories in Shenzhen and Dongguan,China, HT’s team members are dedicated to achieving customer needs through innovative solutions. We provide mechanical components and assembly services to the most recognized names in the Industrial, Transportation & Vehicle, Medical and Consumer markets.

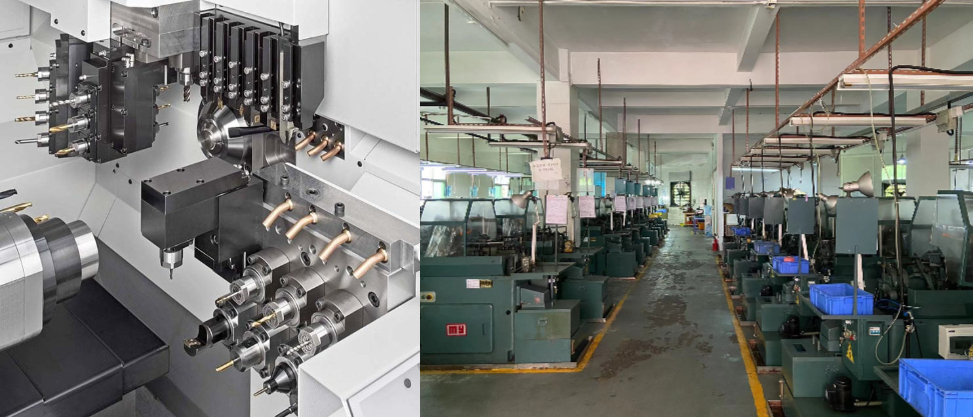

An extensive complement of Japanese and German swiss turning machines provide the precision advantage to meet close tolerances, tight concentricity, fine finish and complex features. HT currently houses 55 sets CNC turning machines and 28 sets CNC milling machines,94 sets automatic lathes and 49 sets cold heading machines and 37 stamping machines

Each new job at HT goes through a detailed development process before the print is released to the production department. We work with the customer’s engineering team to create the appropriate processes and high quality products to meet or exceed customer’s manufacturing objectives with the most cost-effective solutions.